Part 2 of 3.

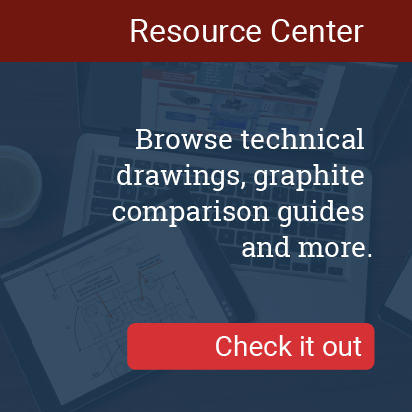

The manufacturing and production of metal matrix composites can be done one of four different ways. There are solid state methods, semi-solid state methods, liquid state methods, and through vapor deposition.

source: slideshare.net/Raghukk/metal-matrix-composites-56710907

Solid State Methods

Solid state methods, as the terminology implies, typically involves two or more solid materials, and these materials are often sandwiched together or infused via thermal or mechanical means. Powdered materials can also act as the matrix material, and these powders are often used to coat the outer layers of a base or reinforcing material.

Powder Blending and Consolidation

Powder blending and consolidation is when a manufacturer takes a powdered metal and some discontinuous reinforcing material, mix them together, and then bond them through a process of compaction, degassing, and thermo-mechanical treatments (often through isostatic pressing or extrusion).

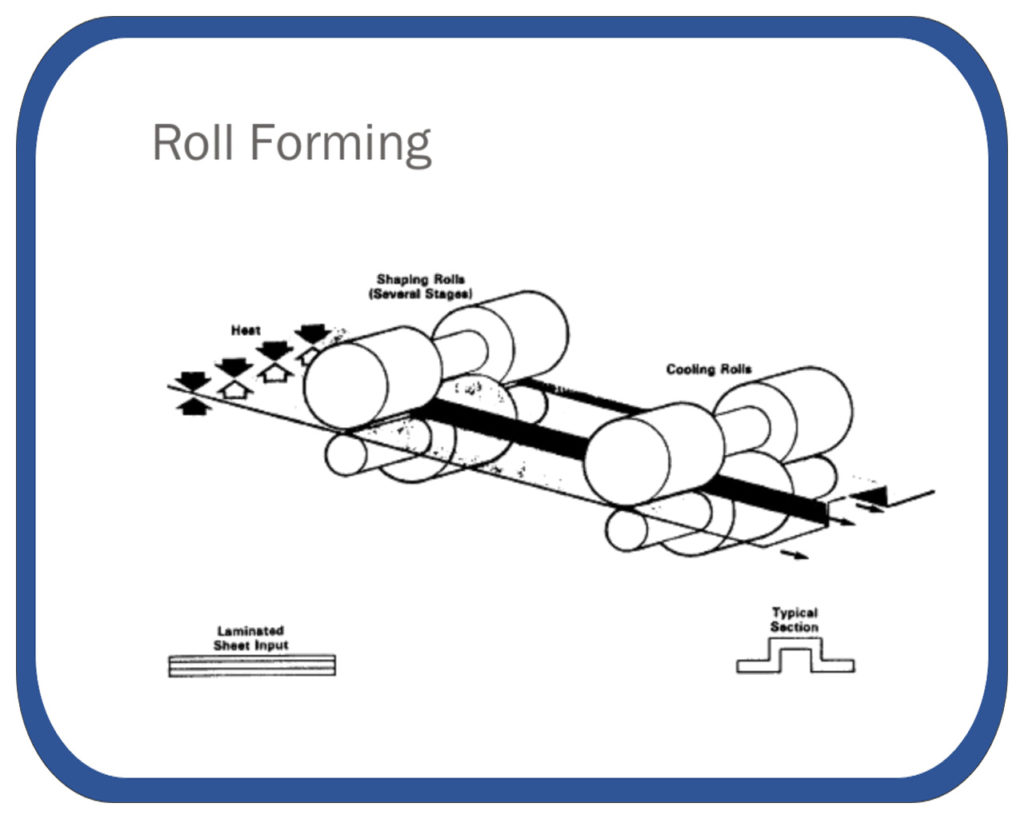

Foil Diffusion Bonding

Foil diffusion bonding is when the manufacturer takes copious layers of some metal foil and then sandwiches long fibers from another material between each layer.

Semi-Solid State Methods

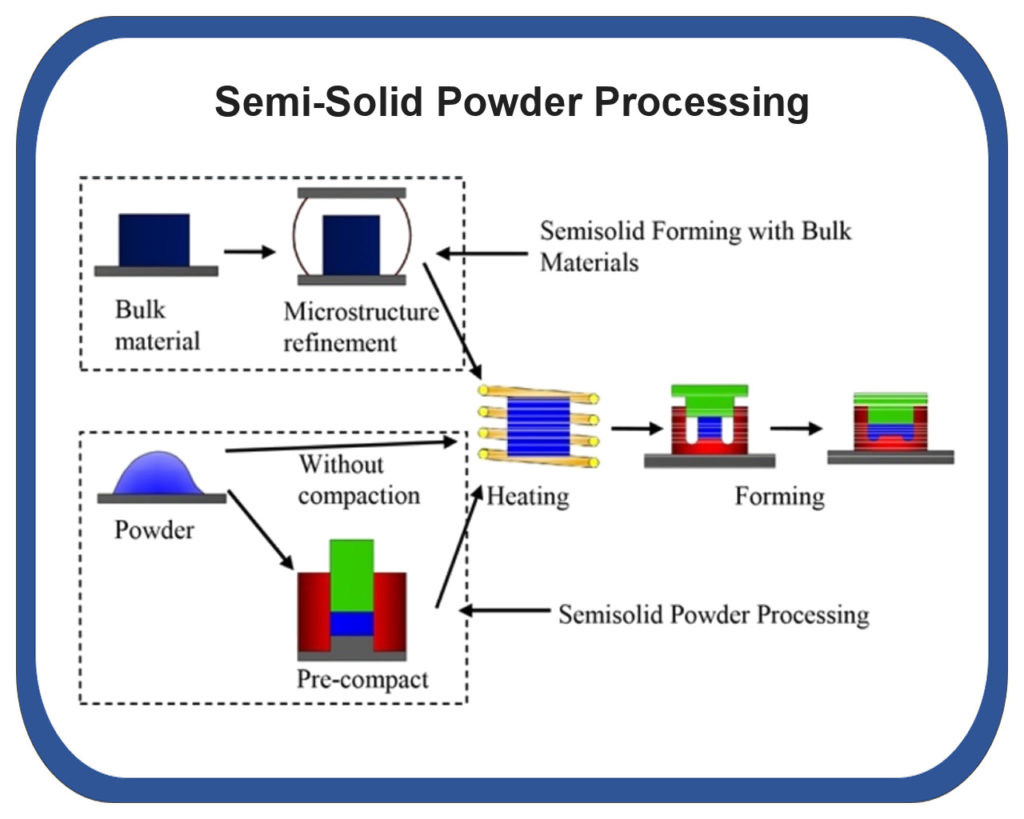

Semi-Solid Powder Processing

Semi-Solid Powder Processing is a process where a powder mixture is heated up to a semi-solid state and pressure is applied to form the composites.

Liquid State Methods

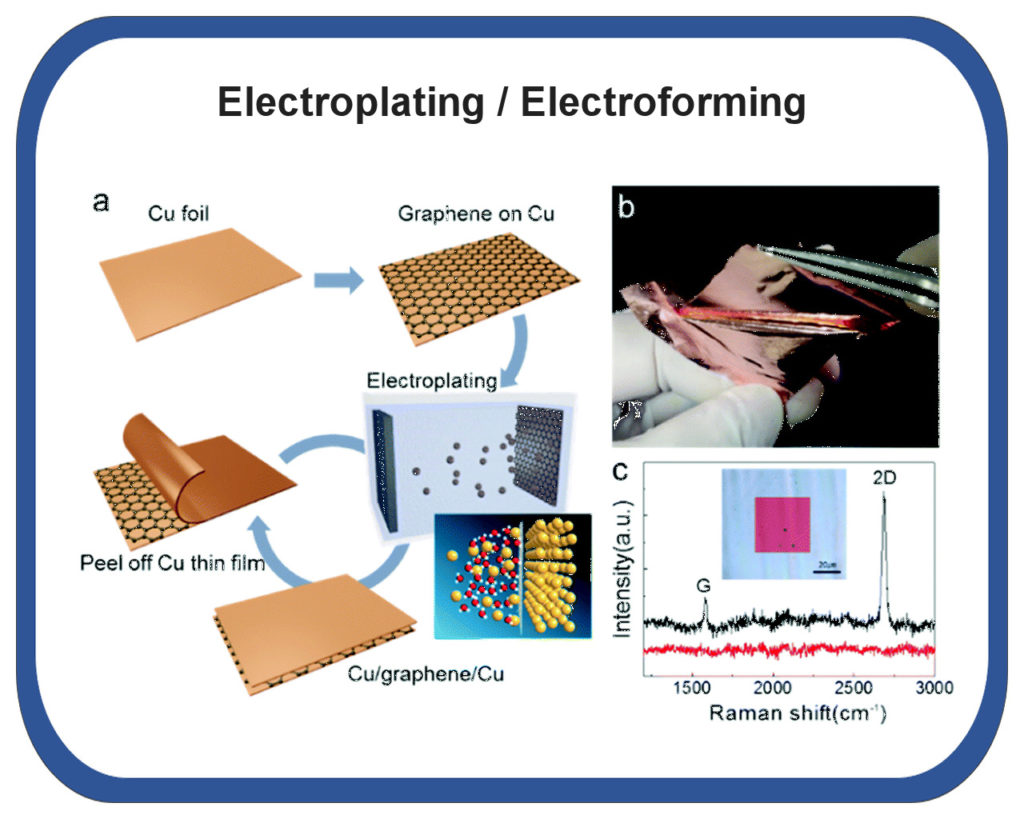

Electroplating and Electroforming

Electroplating and electroforming is a method when a solution containing metal ions loaded with reinforcing particles are co-deposited forming the composite material.

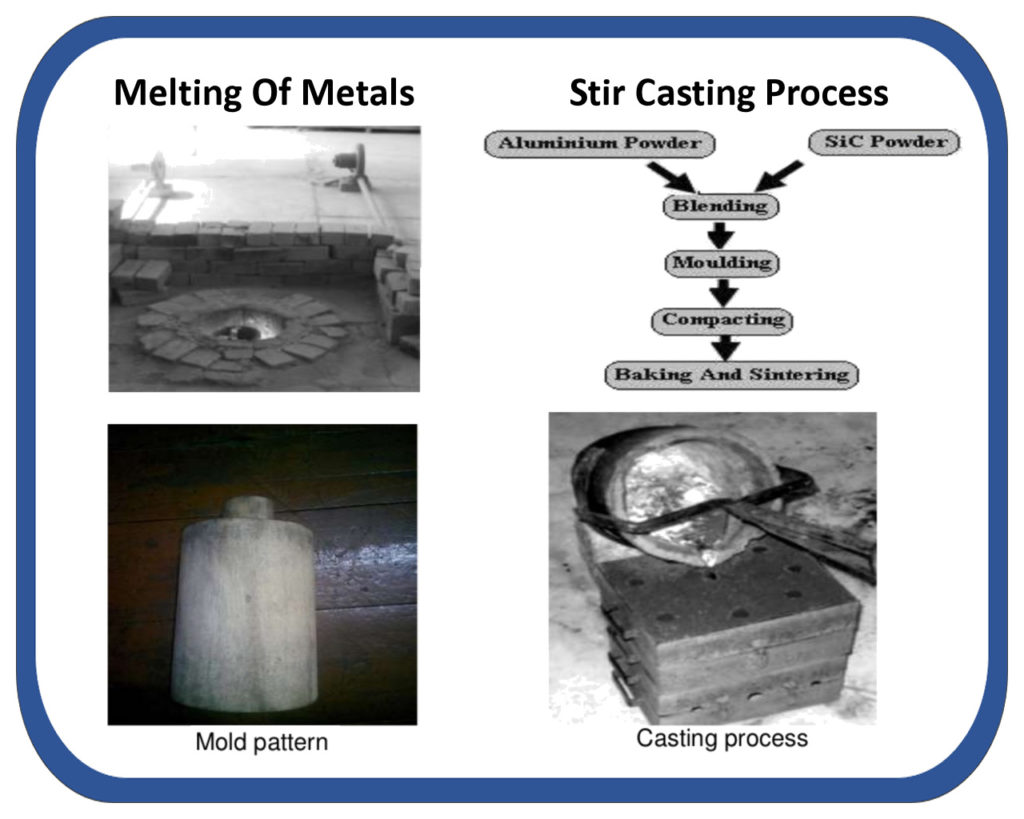

Stir Casting

Stir casting is a method where a discontinuous reinforcement is stirred into molten metal and it creates a composite when it solidifies.

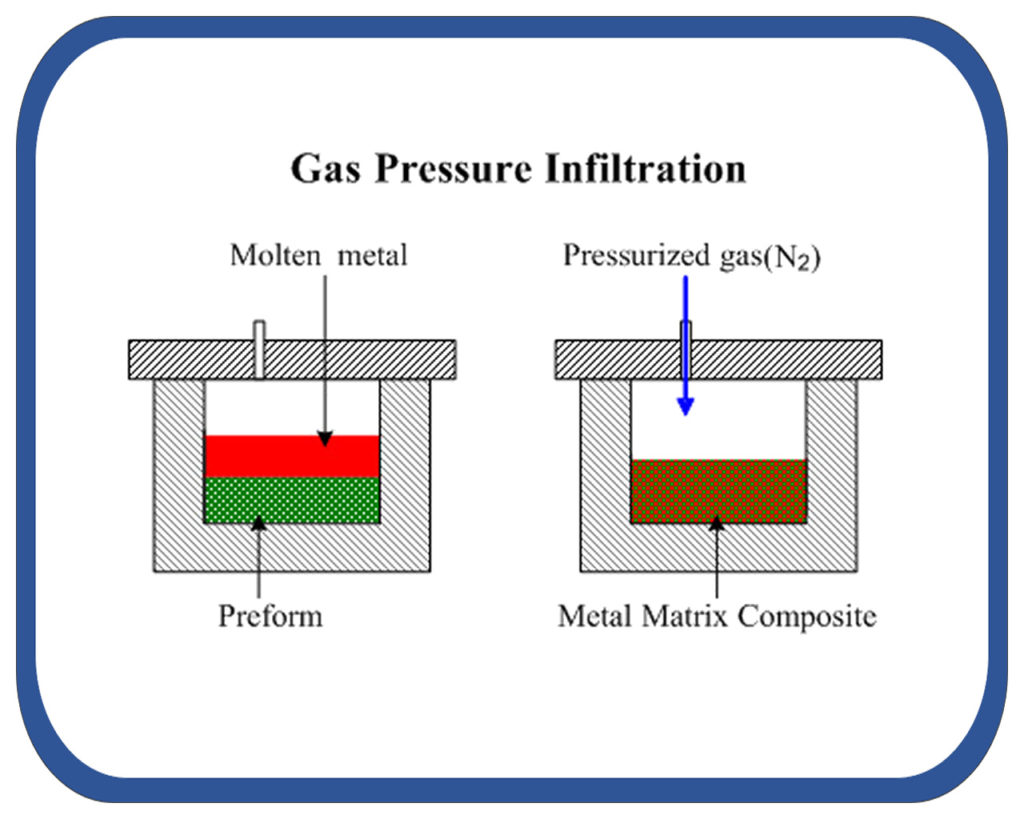

Pressure Infiltration

Pressure infiltration is where a molten metal is infiltrated or impregnated into the reinforcement through a technique involving pressure (typically in the form of gas).

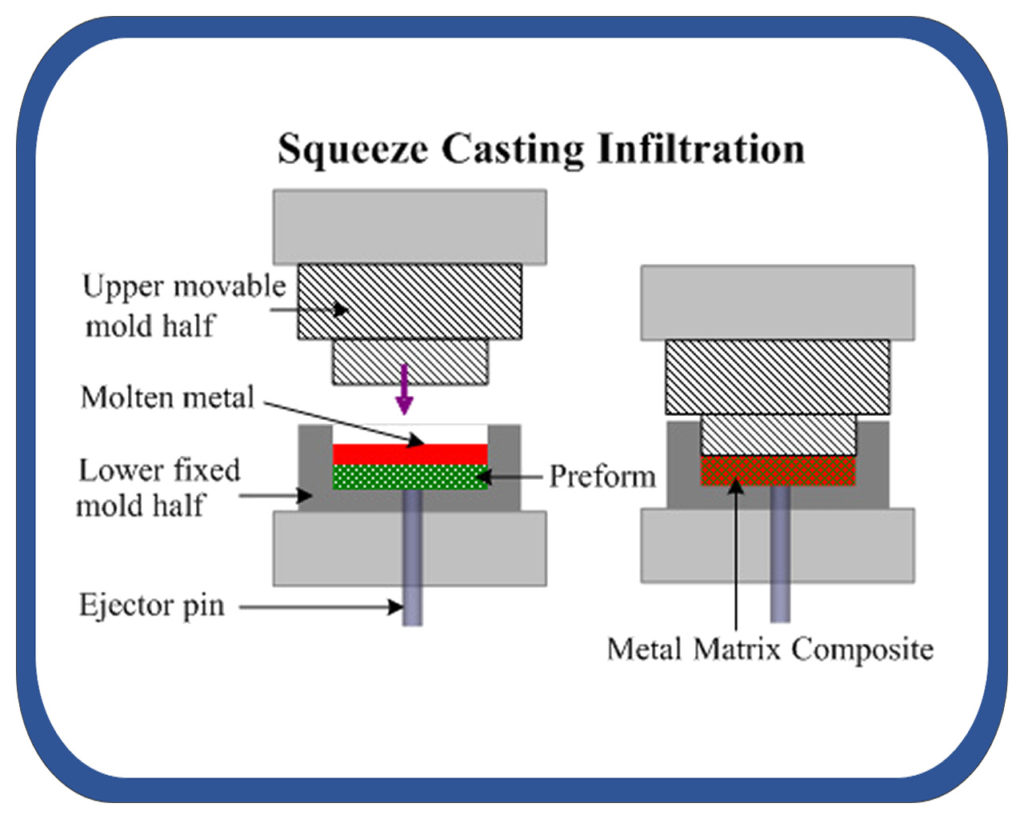

Squeeze Casting

Squeeze casting is a process where molten metal is injected into a form with reinforcing fibers pre-placed inside of it.

Spray Deposition

Spray deposition is a process where some molten metal is sprayed onto a continuous fiber substrate.

Reactive Processing

Reactive processing is processing involving a chemical reaction where one of the reactants forms the matrix and the other forms the reinforcement.

Vapor Deposition Methods

Physical Vapor Deposition

Physical vapor deposition is a process where the reinforcing fiber material is passed through a thick cloud of vaporized metal (coating it).

Learn more about copper and aluminum metal matrix composites from Ohio Carbon Blank.